Fibre optic solutions for the harshest environments

Extending the in-service life of your assets.

Rapid response for world-class operations

Flight simulation

Existing fibres within the cockpit of a flight simulator were being broken due to “jack-knifing” during the removal and replacement of the individual Cockpit Modules (CPM’s).

Military aviation

We designed and manufactured each of the inspection and cleaning guides for all the known fibre optic connectors, both male and female within the Typhoon Fighter Jet.

Mission-critical repair

Working with a leading aerospace client, we provided a solution to replace existing fibres which were being jack-knifed within their flight simulator cockpits.

Serving the Military with mission critical requirements

Alker Fibre Optics is an approved supplier direct to the UK MOD and a trusted partner for a number of specialist prime contractors within the military sector.

Our team are highly skilled fibre optic designers and manufacturers, with expertise in producing reliable high-performing rugged solutions that are of a mission-critical nature.

From emergency repairs and upgrades to bespoke solutions and products, we will improve performance and reliability, extending the in-service life of your assets containing fibre optics in harsh and extreme environments.

Specialist consultancy, tailored solutions

The applications that require stable, dependable high-performing mission-critical fibre optics are ever-increasing and show no sign of slowing in all industries, including academia, research and development.

With over 40 years’ experience, our team of engineers have a legacy of developing bespoke fibre optic solutions for a wide range of market sectors. We hold several protected patents, a testament to our fibre optic expertise and reputation as industry leaders. Once we commit to a client, we’ve yet to encounter a fibre optic problem we couldn’t solve.

Precision manufacturing for critical applications

At Alker, we are proud to produce our tailor-made range of fibre optic solutions at our manufacturing facility in Surrey. Our UK facility means we can fast-track mission-critical components for high-pressure projects including ones destined to the military, this also avoids the complications that ITAR is associated with.

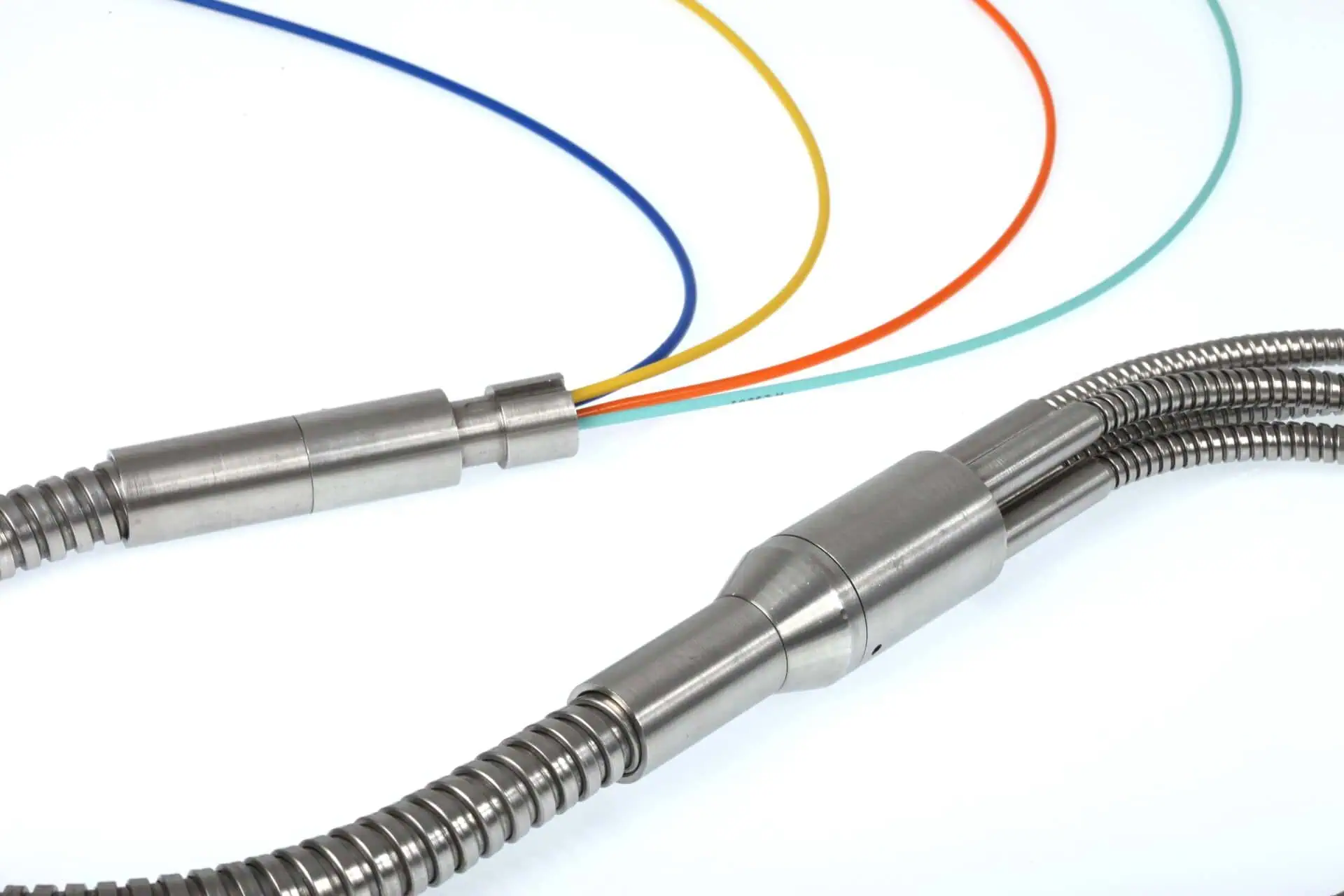

Alker fibre optic splice pipe enclosure

Our fibre optic splice enclosure is a device specially designed to provide maximum protection for vulnerable fibres when splicing is required.

We have designed an innovative range of inline enclosures that are superior to any competing products currently available in the market. The enclosures have numerous advanced features that greatly emphasise the practical benefits.

Armoured assemblies

Alker is a pioneer in the field of innovation, design and the manufacture of fibre optic assemblies for harsh environments, keeping critical components protected.

Bifurcated & trifurcated assemblies

We can create solutions that can be customised to meet specific application requirements, including fibre type, core size, channel count and end face configuration.

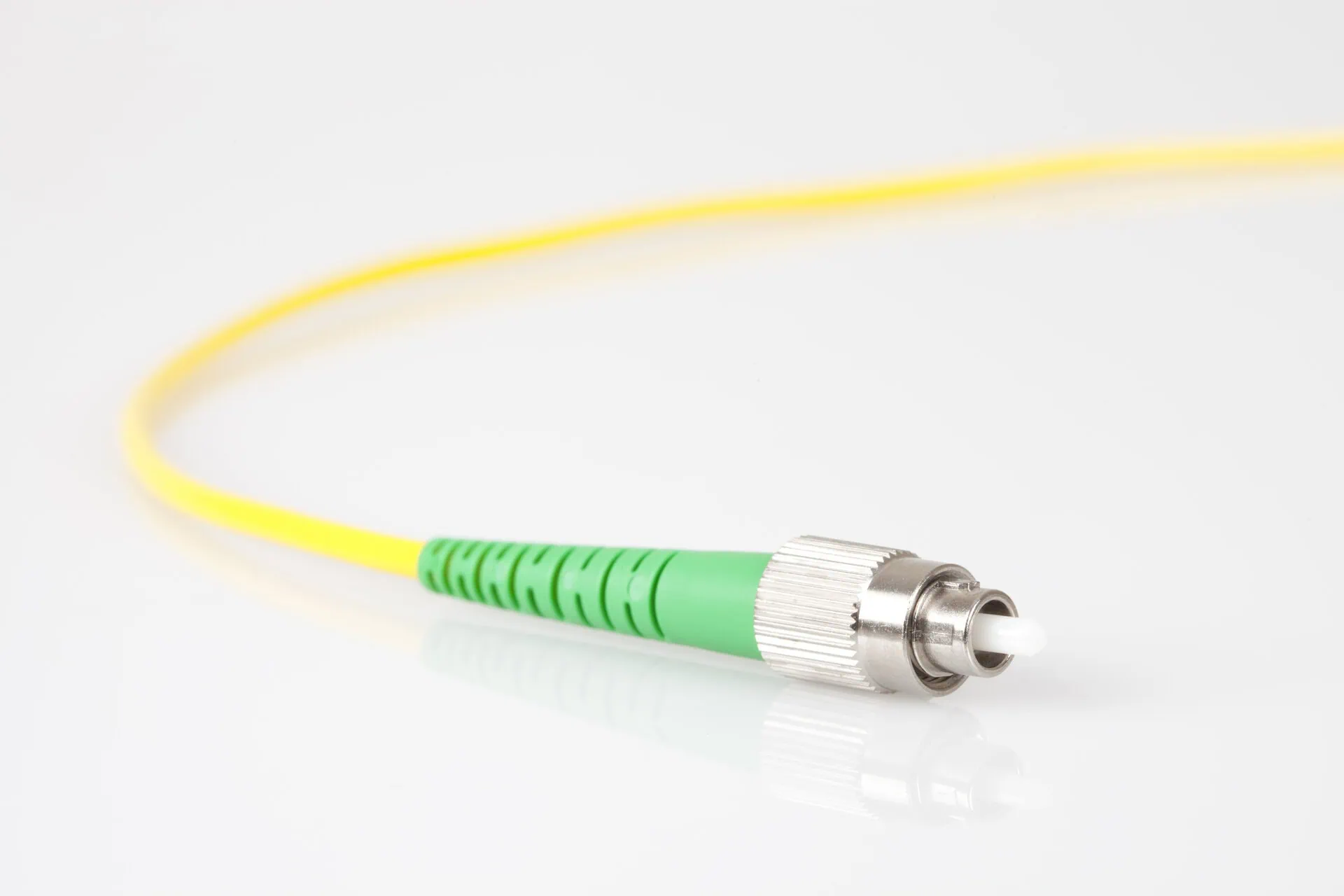

PM fibre optic cable and patchcords

Manufactured at our production facility in Surrey, we offer an unmatched level of specialist customisation for these exacting products with the benefit of minimal turnaround times.

Deployable fibre optic repair kits

Our self-contained fibre optic kit provides all the necessary tools and equipment for the end user to perform their own repairs to accidentally damaged fibre optic assemblies in theatre.

Deployable Fibre Optic Reels

This highly durable hub-less reel system is built around a unique patented design which unitises space within the centre of the reel.

Deployable Backpack System

Weighing in at just 5.7kg, the wearable version of our fibre optic deployable cable reel system has been designed to adjust to different sizes, adaptable for male and female personnel.

Sacrificial Fibre Optic Adaptors

Tailored to each specific set of fibre optic connectors or bulkheads, sacrificial adaptors are an excellent solution to eliminate damage to fibre optic harnesses or bulkheads, which are often attached to mission critical assets.

Responsive repair and trusted support

In response to growing customer demand, we provide comprehensive emergency fault finding and repair support for damaged and faulty fibre optic connections.

The skilled team at our UK manufacturing facility will assess faults onsite to quickly determine the root cause of any issue, carry out repairs, and get you up and running to minimise downtime and disruption.

It’s our commitment to provide a quality service, to minimise future recurring problems and to extend the in-service life of your products.

About Alker

Established in 1985, Alker is a family-run business specialising in the development of cutting-edge fibre optic solutions for industries with notoriously harsh environments.

With innovation at the heart of our business, we provide clients with comprehensive consultancy, underpinned by a wealth of progressive knowledge and experience to design and manufacture specialist fibre optic technology.

All of this is done in-house by our agile team, who will adapt to customer demands, offering fast turnaround capabilities without compromising on quality.

Almost all solutions are unique to each client’s individual needs, manufactured at our design and production facility in Surrey UK which has been tailored to accommodate all project requirements, from individual one-off prototypes and urgent response repairs to the mass production of fibre optic solutions.

Projects delivered

Trusted by industry leaders, Alker is proud to be one of the longest-standing fibre optic solution providers and fibre optic termination houses in the UK.

BAE Systems

NASA

Fred Olsen

Industry leading design

We are always inspired by the challenges that our clients present to us, all looking for a solution bespoke to their specific circumstances. Whether it’s a brand new concept, a sketch of an idea or an existing obsolescent item, to begin the design process, we always turn to the most important source we have, our design and technical engineers.

With the combined fibre optic knowledge they have gained over the years and the historic list of previous design solutions to utilise, a solution is often not far away. In turn, our engineers are backed up with the latest software from SolidWorks 3D CAD, Formlab 3D printer for rapid prototypes and our quality-controlled system through ISO 9001 processes. All our design work, prototype and production manufacturing is all produced within our facility based in Surrey UK.

Discover news, expertise, and innovation

Find out more about our latest news, products, industry trends and innovations here